The typical US truss connector plate is made from Grade 40 structural steel that has been coated with zinc. “High strength” plates are made from Grade 60 steel. In the US, the coating of “typical” plates is called G60, meaning that for every square foot of metal surface, the zinc coating weighs at least .60 ounces. How thick of that coating? Between five and six ten thousandths of an inch.

Is there any 20g plate that weighs exactly a pound? Both the 20g 6x14 and 7x12 are close. A pound of plates (20g) is 87 square inches.

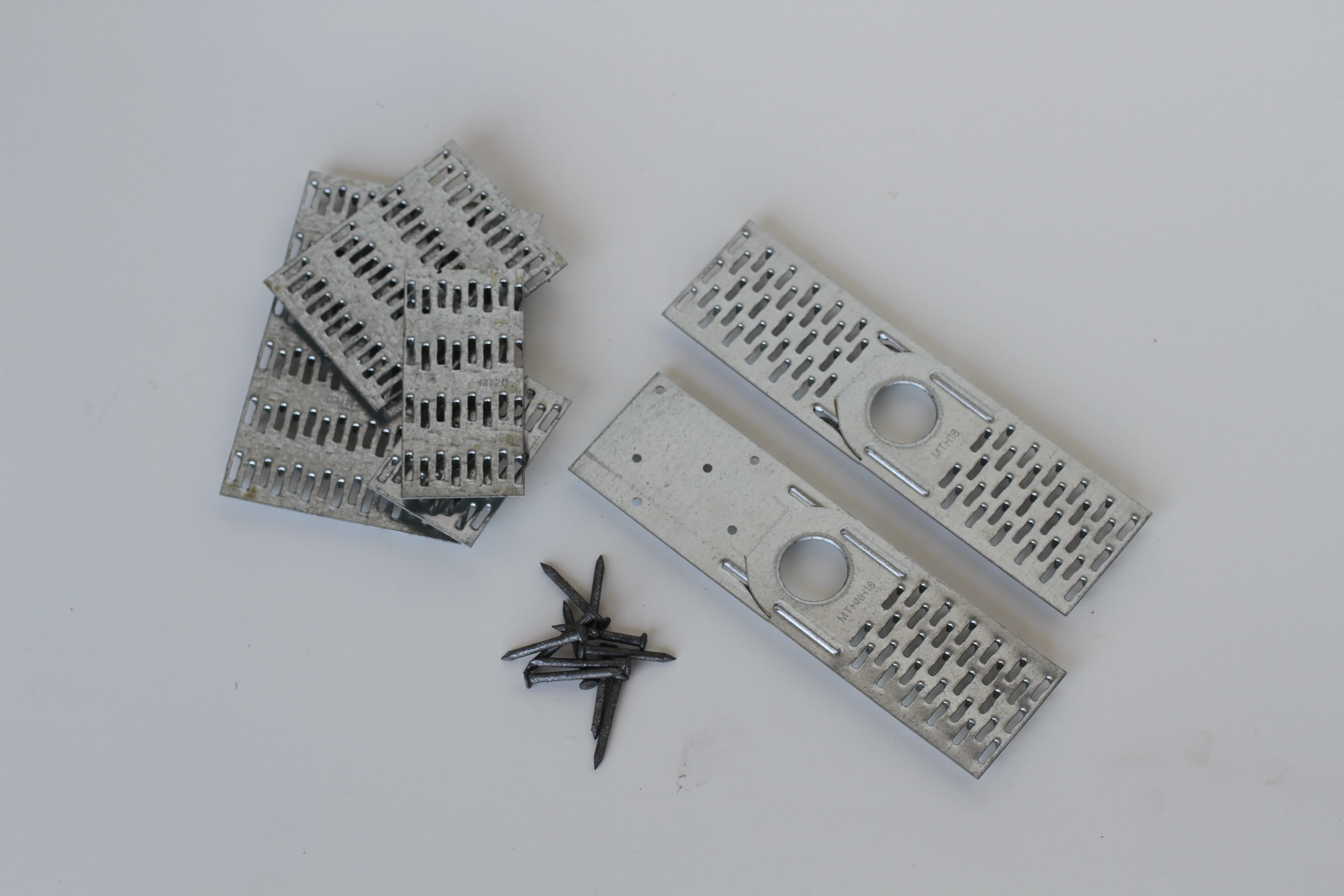

G90 plates

In Canada, where thicker zinc coats are the norm, the “standard” coating is G90. G90 plates cost a little more than “standard” G60 plates in the US.

G185 plates

These plates are sometimes specified in corrosive environments and when specially treated lumber is used. These plates are available in a limited number of sizes, and are about twice the cost of G60 plates.

Stainless steel plates

These plates are also specified for some corrosive environments, come in a very limited number of sizes, and cost 8-10 times more than G60 plates.

Bevel Plates

Bevel plates are available in a small number of sizes and are ideal for certain top chord bearing floor truss situations.

T-plates

The T-plate is simply a T shaped plate that is to be used to increase the top chord bearing reaction limit on certain 4x2 top chord bearing joint configurations (without a block).

Hinge and Half-Hinge plates

Hinge plate are used for manufactured housing trusses and to eliminate the need for a separate “cap truss.” The “half hinge” is used at the peak of hinged trusses to connect the two chords coming together.